Along with the mature of the Internet of

Things technology, the traditional

industrial production lines are upgraded to a new stage of the smart production

line. From the perspective of current technological development and application

prospects, the Internet of Things has been partially applied in the following

areas of industrial field: manufacturing supply chain management, production

process optimization, product equipment monitoring management, and cloud data

statistics etc..

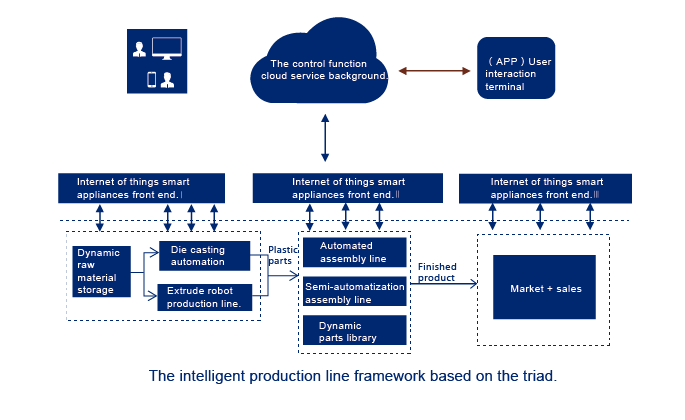

The

smart production line is to use Internet of Things technology and intelligent

electrical equipment of the Internet of Things, to realize real-time connection and control of

the workshop’s automated production line and the Internet of Things cloud

platform. At the same time, according to the changes of market demand, by intelligent

planning and intelligent scheduling of the cloud platforms, to more effectively coordinate the operation

of automated production lines and achieve more efficient intelligent

production.

Taos use various of sensors, based on

industrial Ethernet, industrial software as platform to achieve all-round

intelligent production, transform the company's traditional way of injection molding and products assembly to achieve the coordination of the robot's

intelligent production mode. As shown:

Production mode as picture: